There are many aspects of instrument repair, & within those aspects exist multiple forms of themselves. For example, there are two types of soldering that we must become familiar & comfortable with in the field:

- Soft solder

- This solder is used in places we want to be secure & has a melting point of 360ºF. This is a mixture of low melting point metals, typically copper & tin.

- Silver solder

- This solder is used when we want permanent fixtures in places on the instrument & has a melting point of 1,200ºF. Part of the reason this a permanent bond is because brass aneals at 800ºF. This is a mixture of copper, zinc, & 50% silver.

Soldering is a major skill that we can take with us to other parts of our lives, but with solder the most important thing to consider is: the materials. We use lead-free solder across the board, so make sure you have the right product for the job!

The Porting Tool

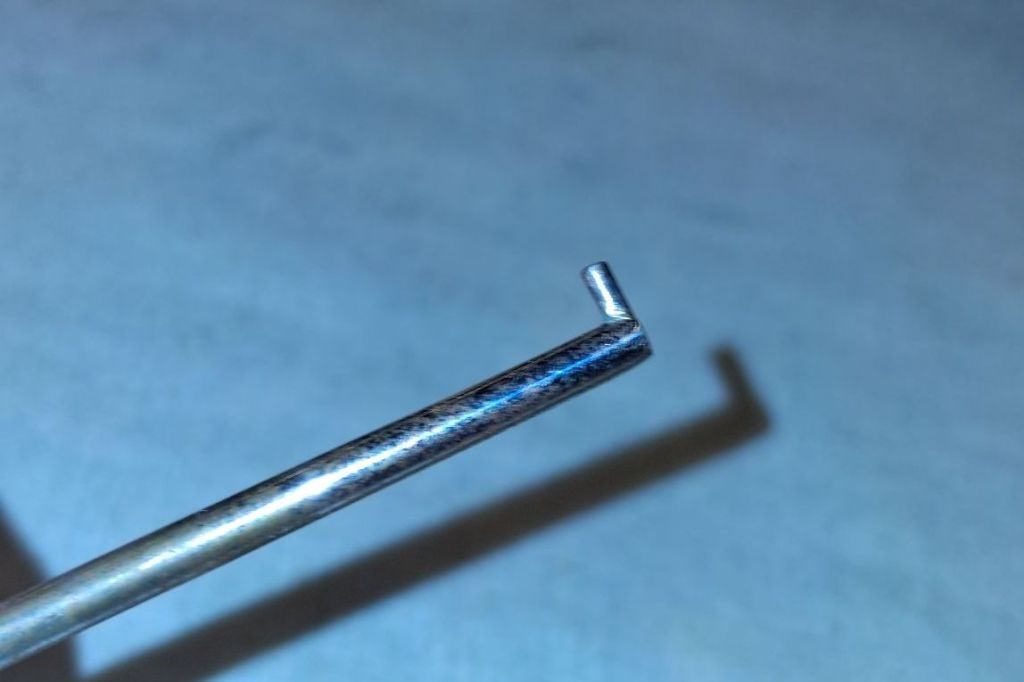

As the name suggests, this is a tool that we must make to help us with porting. Porting is when you make sure the holes in the valve (called ports) are properly aligned with the slides. As you can imagine, anything that gives us more information in confined spaces is a huge advantage to us!

This project also reminds us why it is important to be picky during the construction of our tools. Not only will we be utilizing these tools often, but if thr angle of our pieces are off, it will be much more difficult to make proper.

This tool is made by filing a small notch into a piece of steel & soldering another much shorter piece into that. (Unfortunately, I did not document this process as I went through it.)

I think it is neat you can see how the two pieces are connected with the material. You want to make sure you are distributing your heat properly. Thicker parts will take longer to heat up, so make sure you angle your flame in a way that ensures success! Remember: the flame doesn’t do the soldering, touching the solder to hot metal is what does the soldering.

There are two more projects that discuss heat control: the water key installer & the brace bracket! Heat control is a massive part of what we do with band instrument repair, so it is important we understand how to do it well before we get our hands on a customer horn.

Don’t forget to subscribe (it’s free!).

1 Comment