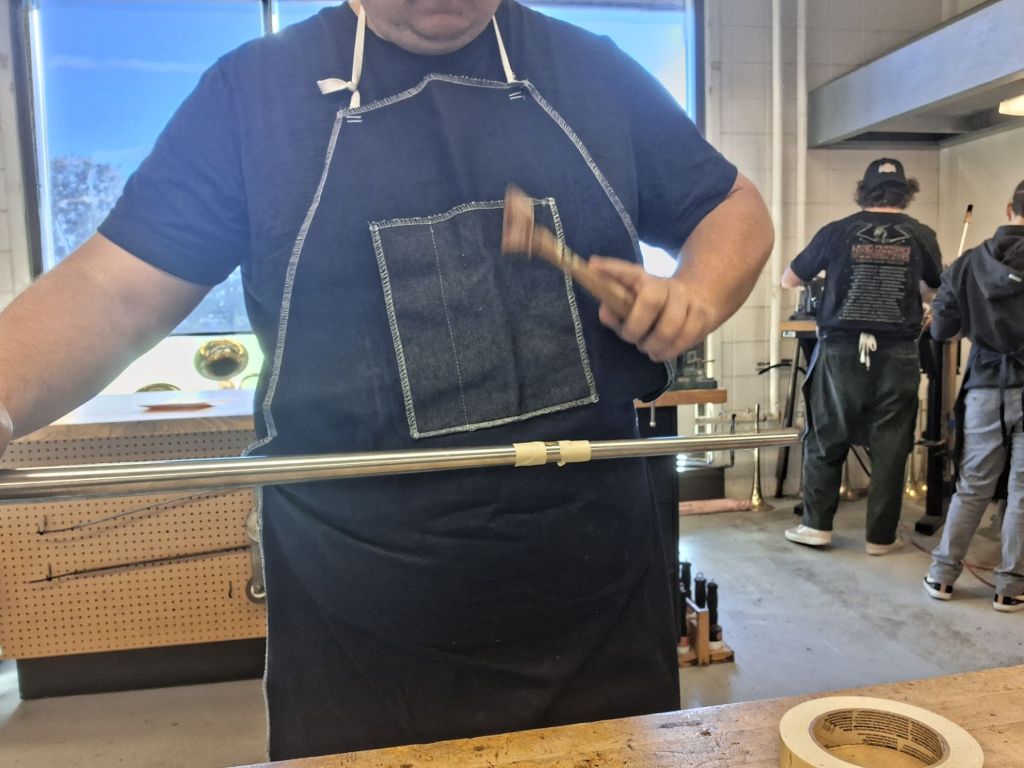

The metal lathe is another extremely valuable piece of heavy machinery in our industry. In the band instrument repair world, we are always creating bits & pieces. Whether it’s a new tool or a hinge rod, or even screws, we can be expected to make & modify throughout our entire career (although, you should be able to make hinge rods & screws at the bench motor.).

Lathes can vary in sizes, but all require the same level of expertise. We should be quite familiar with all the hardware in our shops, no matter now new or old. Some of the lathes in our common shop at the college are over 30 years old & still run like it’s 1995!

It is important to be mindful of your expectations from employers, as not every shop has a lathe or the funds/space necessary to procure such a device. In addition, there is a lot of care & maintenence that goes into a lathe (especially the large free-standing ones), & I bet the techs are the ones that maintain their gear. I have yet to be assigned a project that couldn’t be done on either size lathe.

Beginning Lathe Operations

There comes some new terms with the lathe, as well as formulas for various speeds with consideration for materials. Not all lathes are built the same, & each should be respected as a piece of heavy machinery. Safety should always be practiced, so ensure you aren’t leaning on the lathe or have long hair or clothes draping over your workstation.

Next time, we will be discussing safety in the workshop in a more specific sense. From following standard operating procedures (S.O.P.) to understanding safety data sheets (S.D.S.), there is plenty of information regarding this topic.