If you recall in my post about the porting tool, I mentioned this concept a few times called heat control. It is important as techs that we are conscious of our heat control, regardless of how large or small the current project is. Our handheld butane torches we use at our benches can reach up to 1,200ºF, which is quite toasty! Considering brass anneals typically around the 600º-800ºF range, this is why it is so important we understand this concept. I may even be overstating it, but that is just how important this is to me.

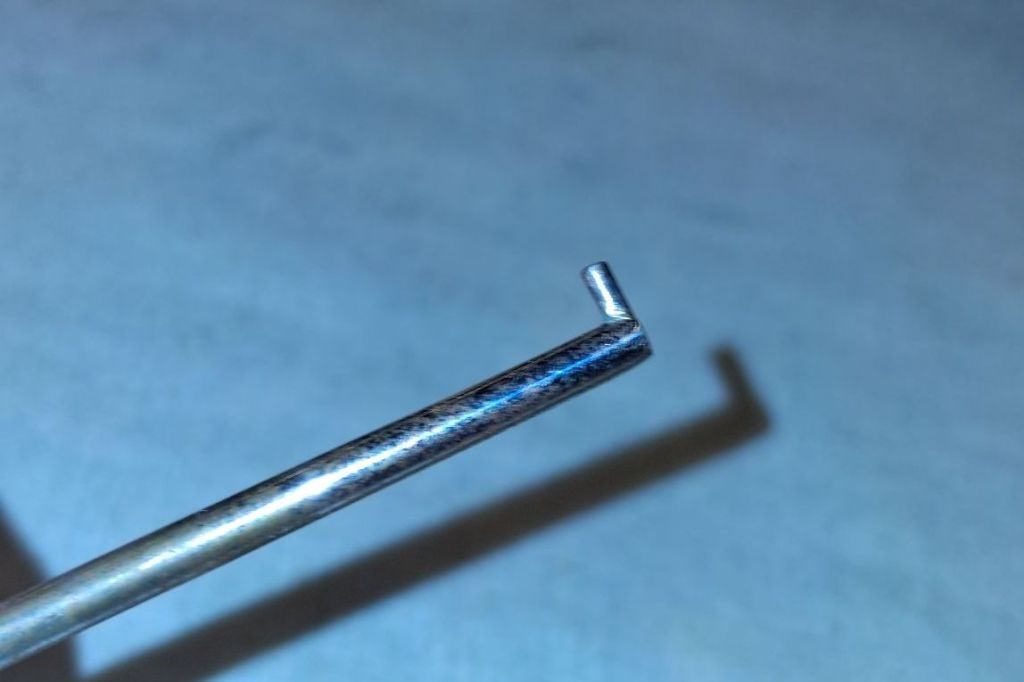

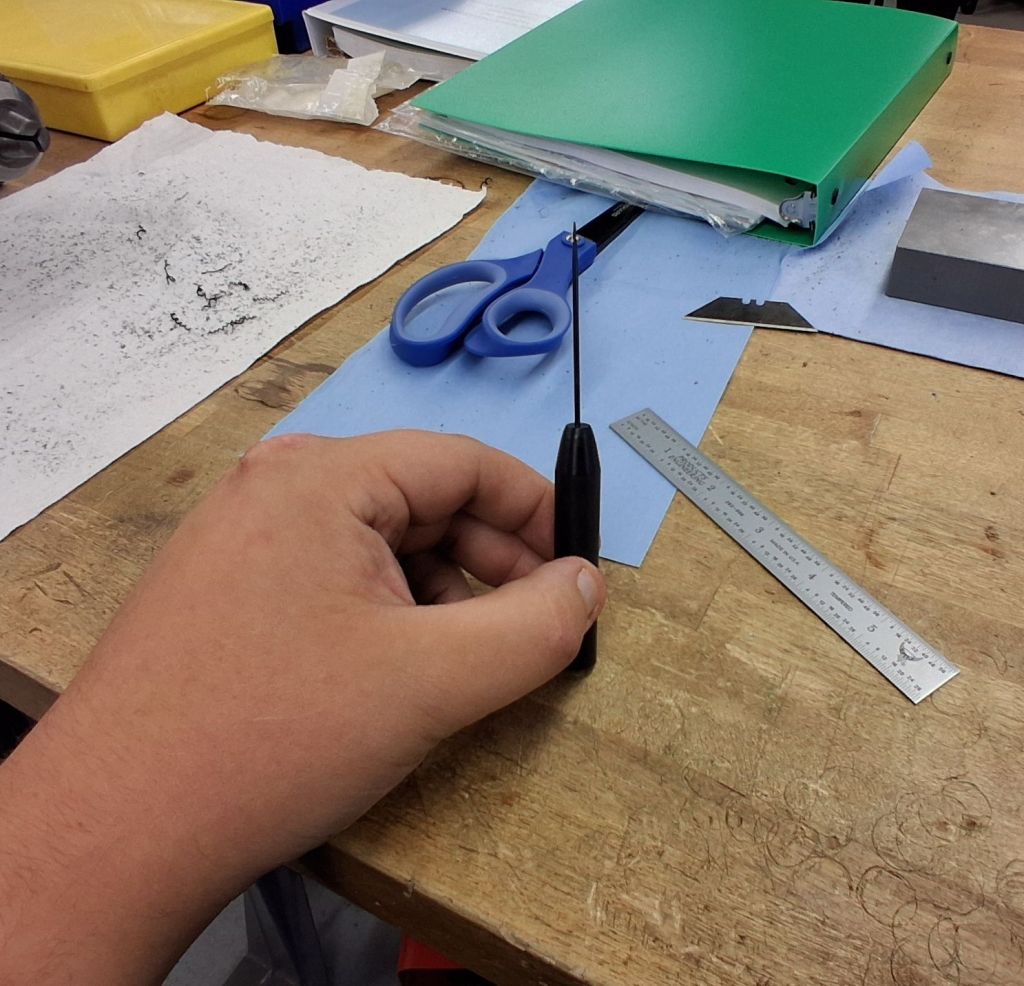

We created this little tool to help us install water key springs easier. Because the metal in those springs is so small, it can cause small yet serious cuts in your fingertips. We need those fingertips to be in as great of condition as possible!

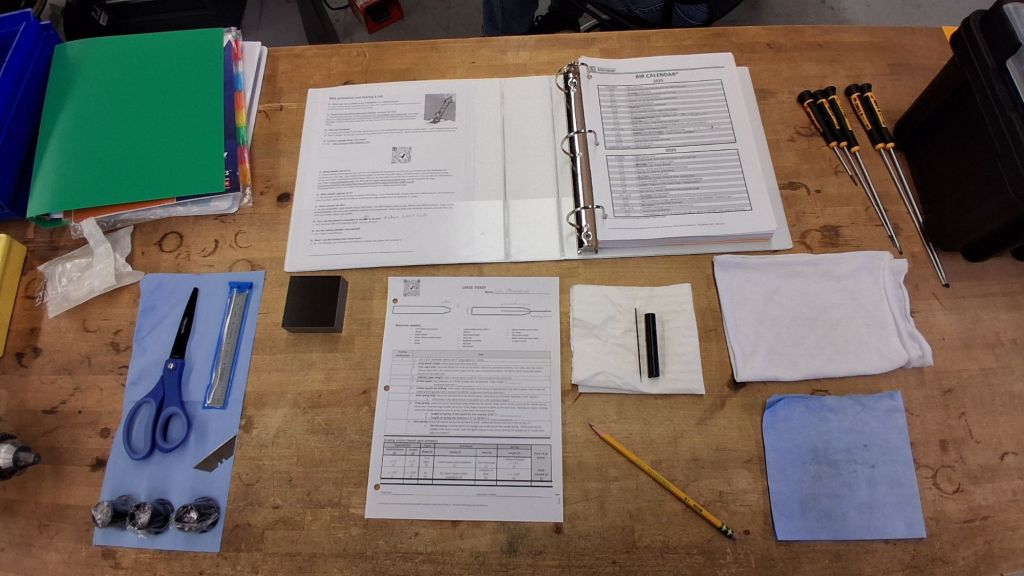

All we do is heat up the small brass rod in the middle (as well as around the middle, make sure you are moving the torch around the material) to make it workable. Most of what we have done so far has been air-cooled, so this is a break in the mold by being the first project we quench in water.

This is a short update, but do not let it dismiss the utility of this tool. I did the water key project about two weeks ago & I still have multiple cuts on my hands from trying to handle the materials manually rather than relying on my tools. This little piece of brass will be a lifesaver!

Don’t forget to subscribe (it’s free!).